Filter by brand

Best sellers

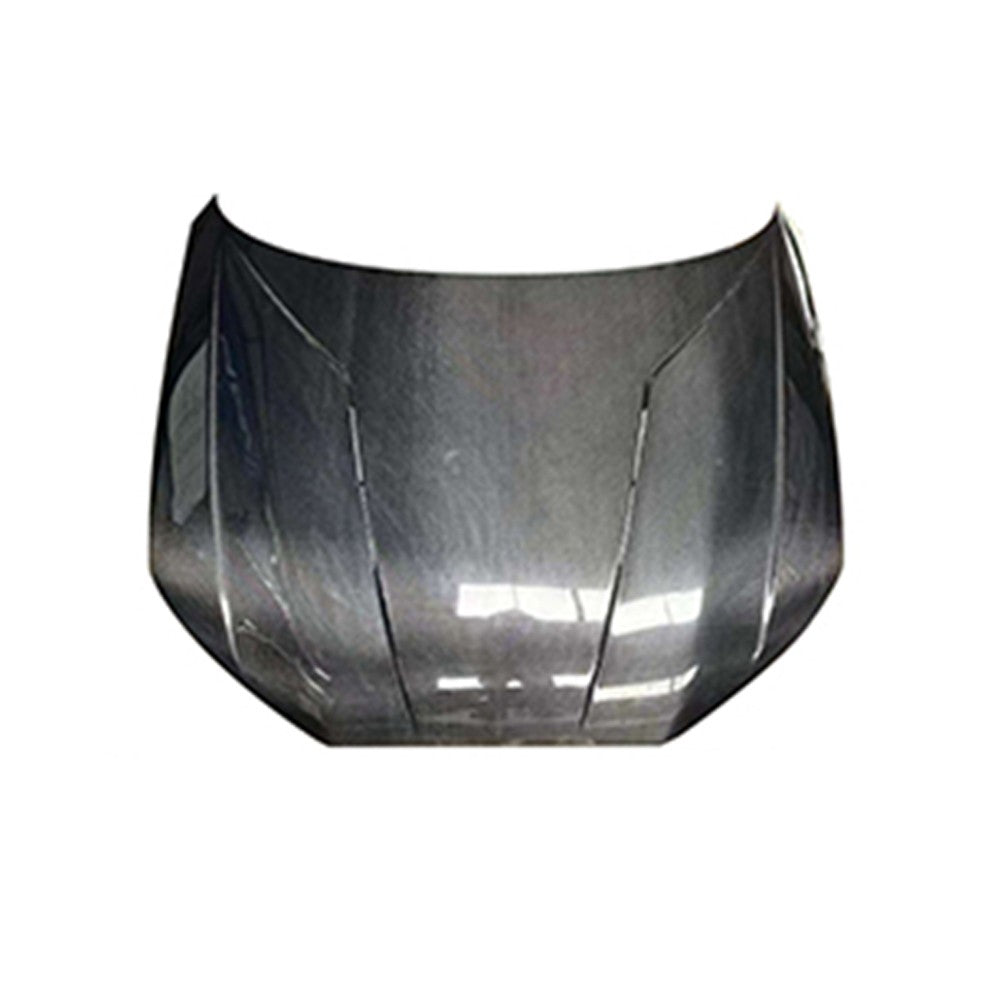

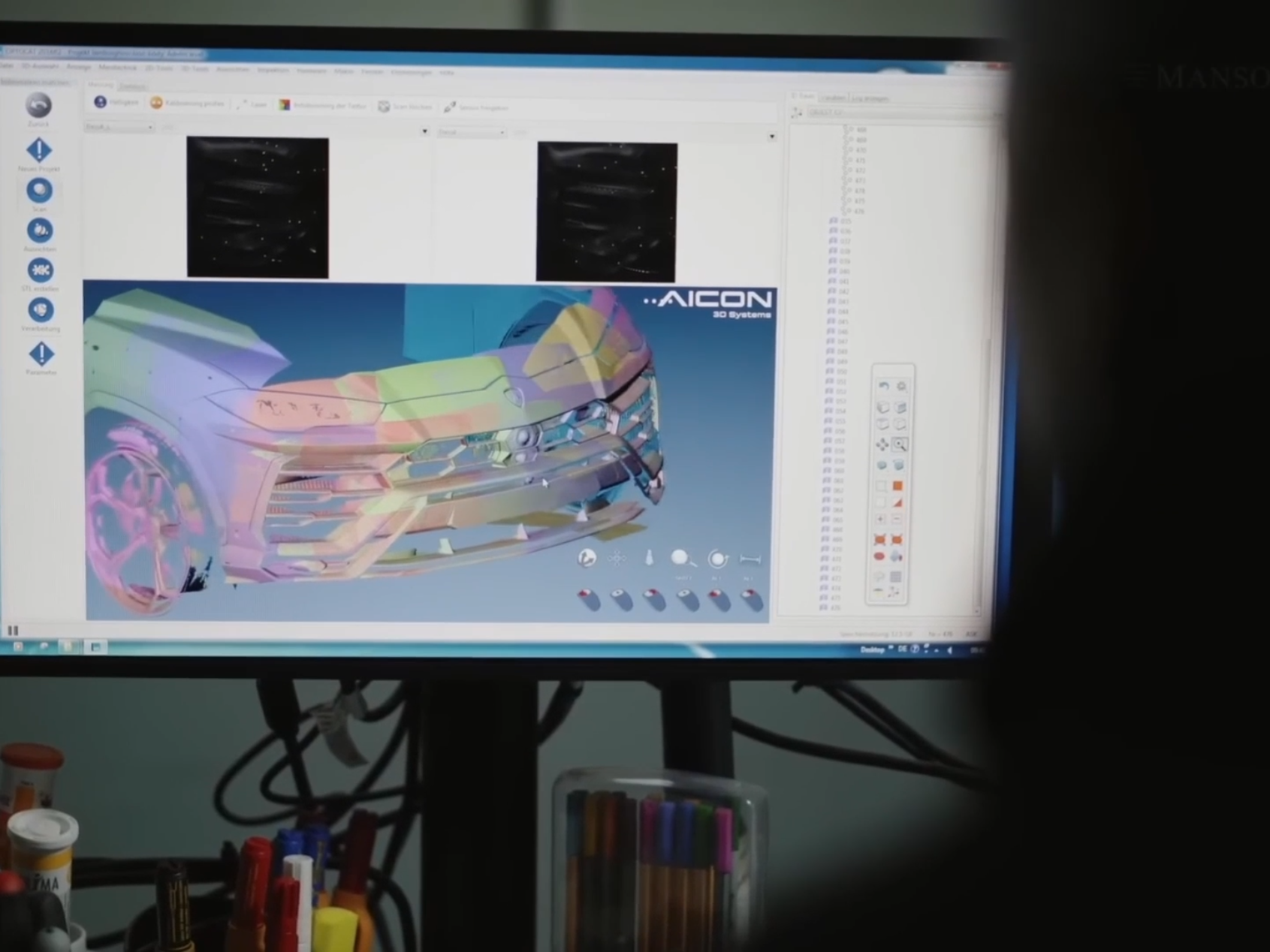

The vision defined

Before

After

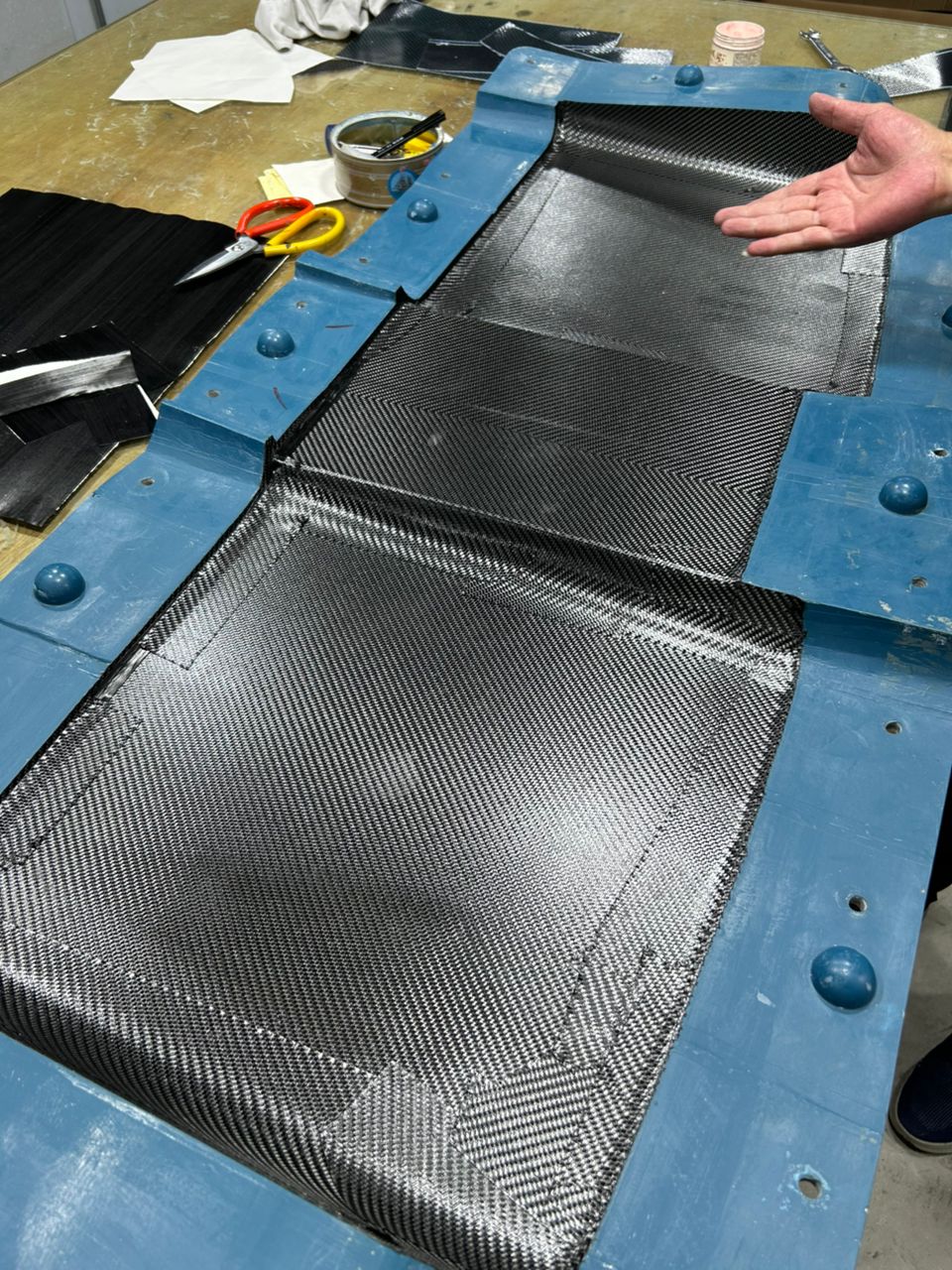

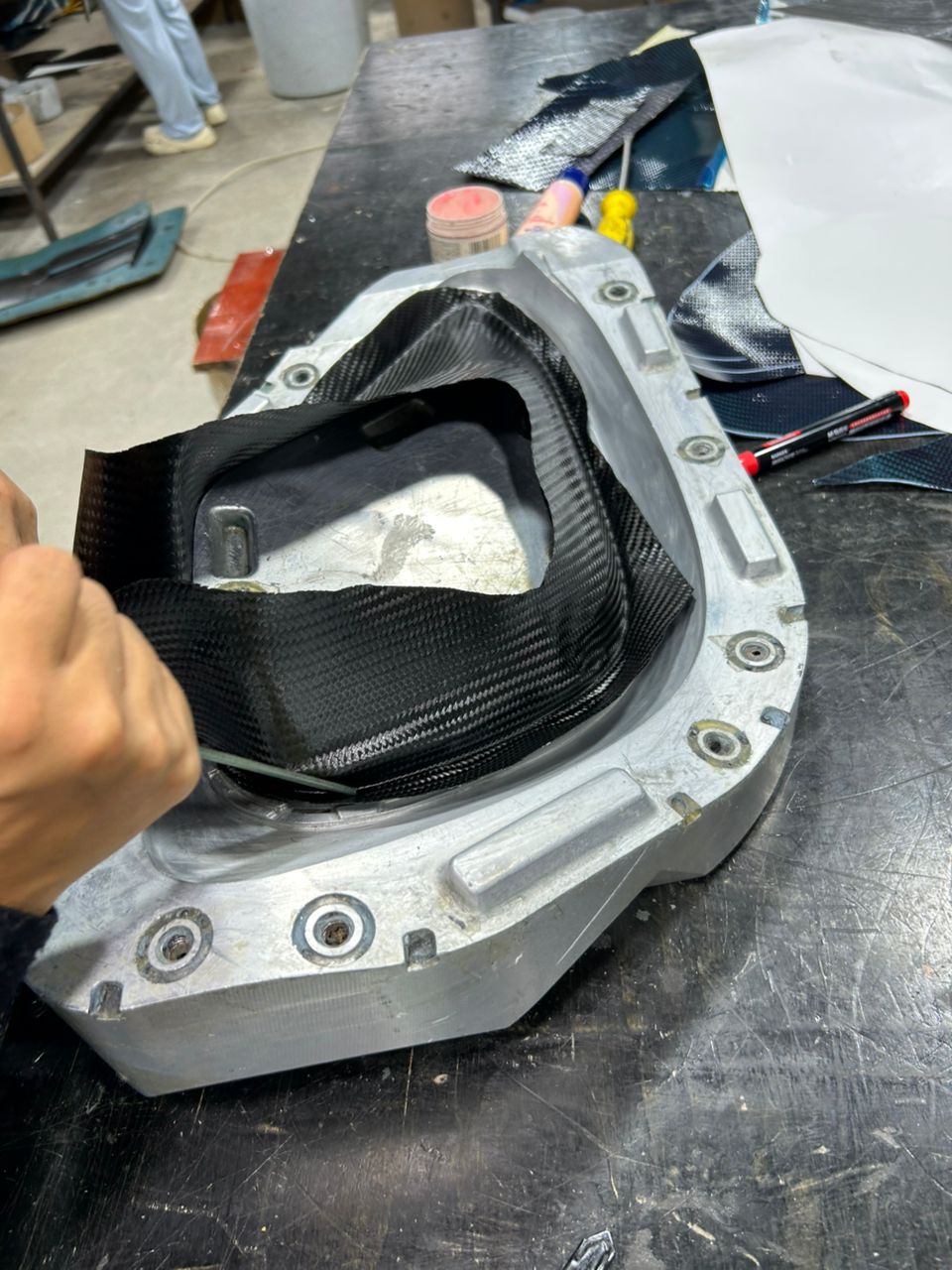

The vision executed

Why we are better

The key differences

VSCarbon

Competition

Why it matters

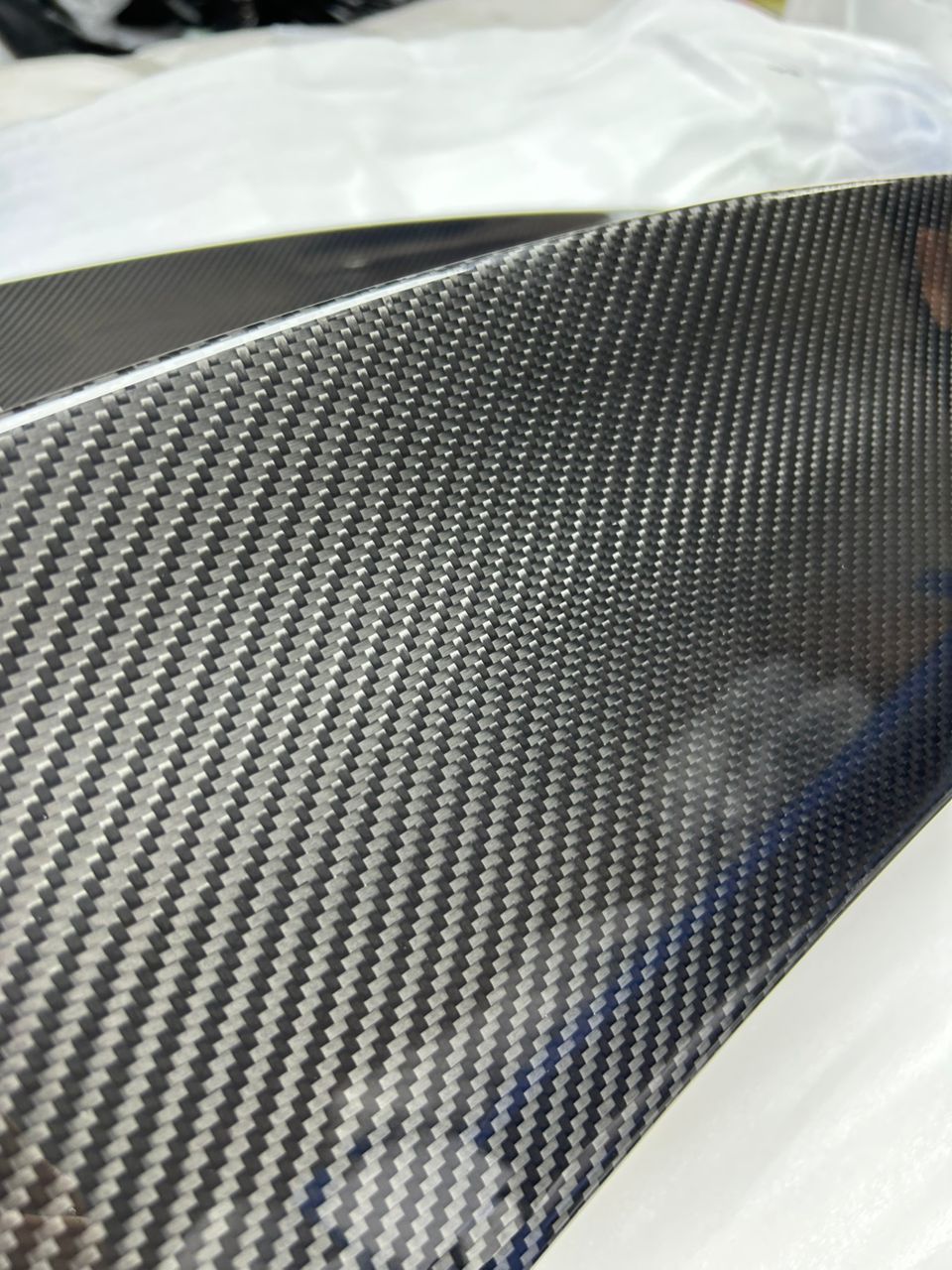

High fiber volume

Lower

Stronger at lower weight

Precisely metered pre-preg

Hand-mixed

Consistent performance

Autoclave pressure + vacuum

Vacuum/oven, no pressure

Denser, fewer voids

Uniform weave, minimal pinholes

More print-through/pinholes

Cleaner, show-grade look

Waterjet trimmed, tight tolerances

Manual trim varies

Bolt-on, OEM-like fit

Automotive-grade clear (matte/gloss)

Varies; can yellow

Stays clear for years

High-Tg resins (120–180 °C)

Lower-Tg systems

Won't soften near heat

Optimized layups

Heavier for same stiffness

Better power-to-weight ratio

You got questions. We got answers.

Check out the most common questions our customers asked. Still have questions? Contact our customer support.

Do you ship overseas?

Yes, we ship all over the world. Shipping costs will apply, and will be added at checkout. We run (shipping) discounts and promotions all year, so stay tuned for exclusive deals.

Do I need to setup an account to place an order?

You do not need to set up an account to place an order. However creating an account allows you to store your shipping information, see order history, and view your product’s warranty information. We use Shopify's integrated 'Shop' feature for optimal integration and security.

How long will it take to get my orders?

It depends on where you are. Orders will be processed the same day and shipping usually will take 5-7 business days. Delivery details will be provided in your confirmation email.

What is your return policy?

All products purchased from our website may be returned within 14 days of purchase for a full refund less shipping costs. International return orders may be subject to return shipping fees. To initiate such a return please reach out to our service team via the contact page.

Any more questions?

Please feel free to contact our service team via the contact page! We will be happy to assist you.